Skip to the content

OUR STRENGTHS

- Comprehensive study of customer needs and custom solutions for specific requirements.

- Capacity to build complete systems that includes mechanical structure, electric motor, lubrication and cooling systems, and integration of data acquisition and VFD based control.

- Skilled team with high-speed rotating equipment background (balancing, critical speeds, vibration and modal analysis and precision metrology, and tribology).

ENGINEERING SERVICES

- Product specification review and customer data analysis.

- System Design, drafting and model development.

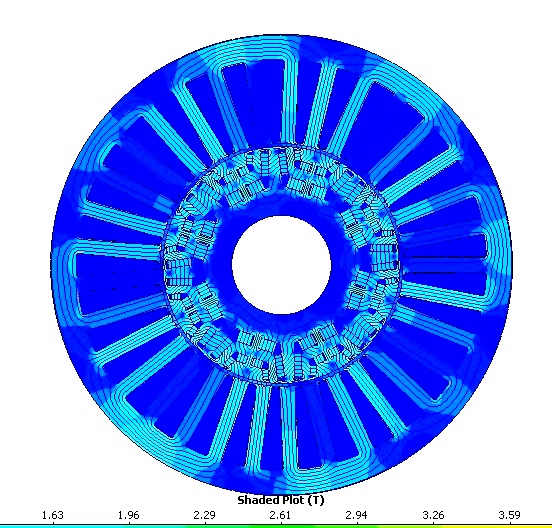

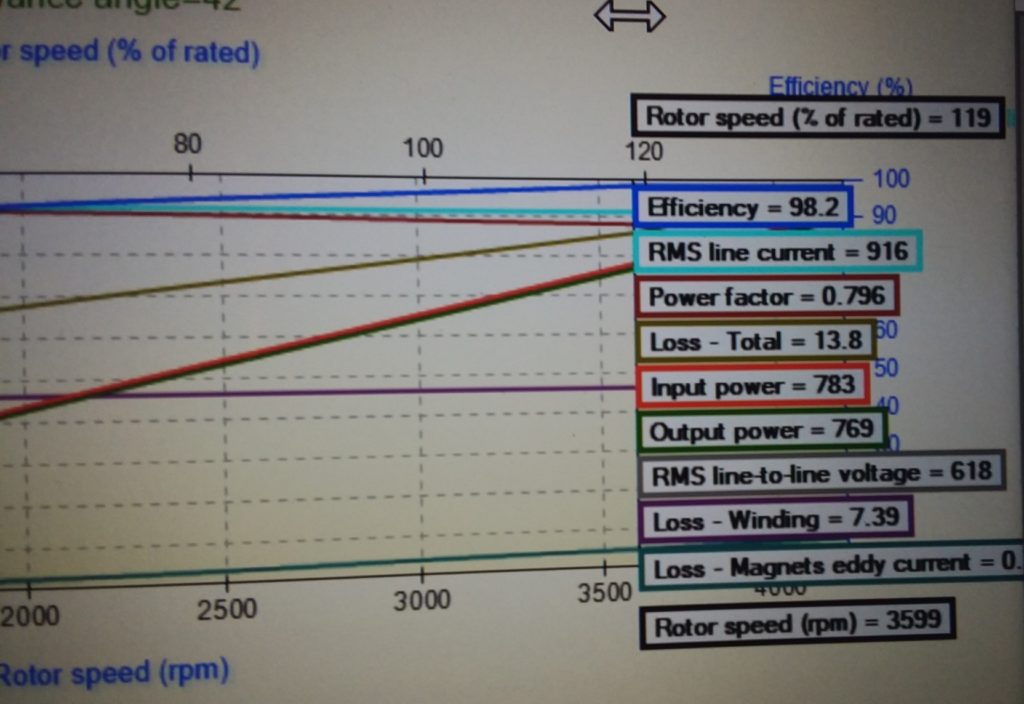

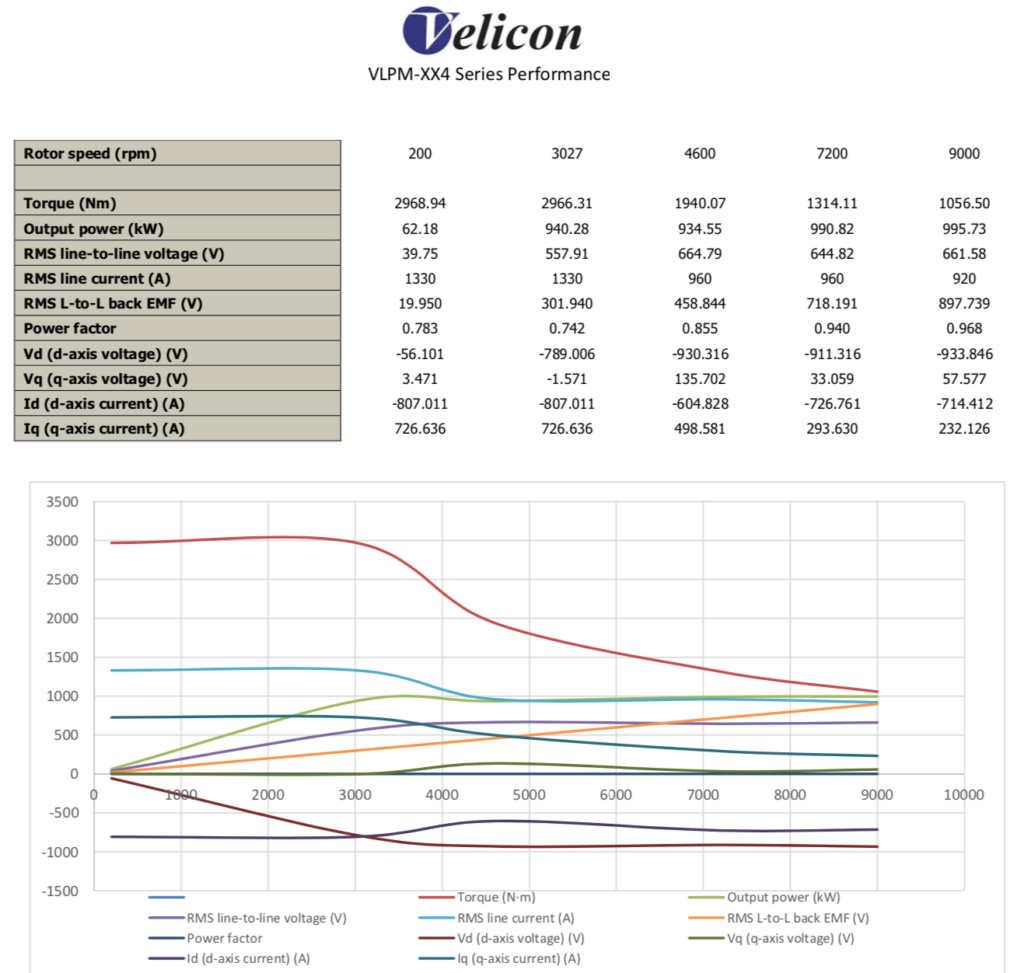

- Component design focused on mechanical, magnetic & thermal analysis using FEA methods.

- Coil winding insulation process development.

- Tooling & fixturing development and CNC program development.

- Computer aided manufacturing process (CAM) implementation.

PRODUCT SUPPORT SERVICES

Service and Installation Support:

- In process quality assurance based on ISO 9001 and MIL standards.

- In-house testing of final products before delivery.

- Installation support

- Start up and commissioning

- VFD programming and data acquisition set up

- System diagnosis and debugging

- Balancing, bearing run-in and temperature stabilization

- Vibration analysis, modal analysis, and trim balancing

- Preventive maintenance support